America’s Water Infrastructure Act

America’s Water Infrastructure Act of 2018 debriefed

America’s Water Infrastructure Act of 2018 (S. 3021, Pub.L. 115–270) is a United States federal law that provides for water infrastructure improvements throughout the country in the areas of:

• flood control

• navigable waterways

• water resources development

• maintenance and repair of dams and reservoirs

• ecosystem restoration

• public water systems (1)

• financing of improvements

• hydropower development

• technical assistance to small communities.

Much of the bill revolves around the Corps of Engineers. The law also reauthorizes the Water Infrastructure Finance and Innovation Act of 2014 (WIFIA) which provides expanded financial assistance to communities under the Clean Water Act and Safe Drinking Water Act.

In terms of Water Resources Infrastructure and Drinking Water System Improvement – excerpts that may affect water managers include:

(Sec. 1401) The bill authorizes specified water resource projects in Arkansas, Puerto Rico, Texas, Washington, California, Hawaii, New York, Florida, and New Mexico. The bill also authorizes project modifications for previously authorized projects in Georgia, Michigan, and Tennessee.

(Sec. 2001) The EPA must implement a program for connecting, expanding, or repairing existing public water systems that are on Indian reservations in the Upper Missouri River Basin or the Upper Rio Grande Basin.

(Sec. 2002) The Safe Drinking Water Act is amended to authorize states to use their drinking water state revolving funds (SRFs) to protect certain source water areas.

(Sec. 2003) The EPA must study and report on intractable water systems (small drinking water systems with a history of significant noncompliance with such Act) and barriers to delivery of potable water to individuals served by such systems.

(Sec. 2005) The EPA may issue grants to assist: (1) underserved communities with contaminated drinking water, and (2) water systems with programs or projects that increase the resilience of drinking water infrastructure to natural hazards.

(Sec. 2006) The EPA must provide grants to: (1) address lead contamination in drinking water at schools and child care programs; and (2) accelerate the development and deployment of innovative water technologies that address pressing drinking water supply, quality, treatment, or security challenges.

(Sec. 2008) The bill expands requirements concerning consumer confidence reports issued by community water systems.

(Sec. 2010) The EPA or a state with primary enforcement authority responsibility under the Act may require the owners or operators of certain public water systems that have repeatedly violated national primary drinking water regulations to consolidate or transfer ownership.

(Sec. 2011) The EPA must develop a strategic plan for improving the accuracy and availability of compliance monitoring data.

(Sec. 2012) Within five years and every five years thereafter, the EPA must review and update educational materials concerning best practices for asset management strategies that may be used by public water systems.

(Sec. 2013) The bill expands risk assessment requirements for community water systems to include risks from natural hazards and creates a grant program within the EPA called the Drinking Water Infrastructure Risk and Resilience Program.

(Sec. 2014) The bill: (1) reauthorizes through FY2021 the public water system supervision grant program and the source water petition program, and (2) reauthorizes through FY2021 and revises the drinking water SRFs.

(Sec. 2017) The EPA must review and report to the public on existing and potential methods, means, equipment, and technologies for the treatment and distribution of drinking water.

(Sec. 2018) The Emergency Planning and Community Right-To-Know Act of 1986 is amended to ensure that states and community water systems are notified of a release of a contaminant into their source waters.

(Sec. 2019) The GAO must study and report on demonstrations of compliance with a state or local environmental law that may be substantially equivalent to demonstrations required by the EPA for compliance with a cross-cutting requirement (i.e., a requirement that is a condition for obtaining loan or loan guarantee under the Safe Drinking Water Act).

(Sec. 2020) The bill authorizes additional grants for SRFs in order to aid certain community water systems that were affected by natural disasters after January 1, 2017.

(Sec. 2021) The bill: (1) expands requirements for public water systems to monitor unregulated containments, and (2) extends through FY2023 a requirement that water system projects financed through a drinking water SRF program only use iron and steel products that are produced in the United States.

(Sec. 2023) The bill reauthorizes through FY2021 and revises the drinking water SRF.

The entire bill can be read here:

https://www.congress.gov/bill/115th-congress/senate-bill/3021/text

(1) The US Safe Drinking Water Act and derivative legislation define “public water system” as an entity that provides “water for human consumption through pipes or other constructed conveyances to at least 15 service connections or serves an average of at least 25 people for at least 60 days a year.”

Over 286 million Americans get their tap water from a community water system. Eight percent of the community water systems—large municipal water systems—provide water to 82 percent of the US population.

Source: United States Government

https://en.wikipedia.org/wiki/America%27s_Water_Infrastructure_Act_of_2018

Source: Wikipedia

https://www.cdc.gov/healthywater/drinking/public/index.html

Source: CDC

https://www.congress.gov/bill/115th-congress/senate-bill/3021

Source: United States Government

Cold Weather Effects on Municipal Water Supplies

Municipal Wells

Although it might not make sense, household water use actually goes up during winter. Think about it, more people spend their time indoors. So when you factor in high-water demands, cold weather challenges for a municipal water supply are magnified.

Most obvious, harsh winters increase risks for elevated tanks, pipes and valves to fail — especially during night when water demand and turnover rate is low. Most temperature-related problems, however, can be prevented with appropriate planning, maintenance and inspections. For example, flowing water is less prone to freezing. Moving water in and out of elevated tanks and mixing systems can lower the risk of failure.

Of particular nuisance for water utilities is frazil ice – a loose collection of slushy ice that forms on cold, clear nights when water temperatures are near freezing. Frazil ice forms at the surface and is notorious for blocking submerged raw water intakes – shutting down pumps. To avoid problems with freezing in the plant and distribution system, sealing external openings and insulating facility buildings, pump and disinfection booster stations can reduce heating loss and cold air penetrations.

For home owners, lateral lines leading from a utility-owned water main through the yard to a home are particularly susceptible to freezing under the roadway or sidewalk where there is no grass or snow to provide an insulating barrier between the cold air and buried pipe.

Winterizing Tips For Water Utilities

Residential Wells

Cold has no apparent negative affect on the equipment nor well, in part, because the well and equipment are sealed on the outside. The well cap and casing serve as insulation in a closed system. Lateral pipes that carry water from your well to a distribution source should be below the frost line. In addition, even during the most severe winter or hottest summer, the ground water held by your well generally stays at approximately 55 degrees year round. Though water levels have been known to drop in winter due to atmospheric pressure – the consistent water temperature keeps most of the equipment in a constant state far from freezing.

Effect of temperature on ground-water levels

As the use of submersible data loggers increases, more and more questions about what to do during the winter months are raised. Should I remove them from the environment? What happens if they freeze? Will they record accurately in the colder temperatures? Can I trust the data recorded at lower temperatures? These answers frequently are … Continue readingCold Weather & Dataloggers

Machining Excellence

Brotcke Well & Pump’s machine shop is located at our Fenton office. Complete machine shop services are available to ensure timely and professional repair of both vertical turbine and horizontal pumps. Specialized components or standard pump parts can be fabricated to reduce downtime. BWP has a Schenck Horizontal Balancing Machine to complement our machine shop equipment. The Schenck equipment provides high tolerance balancing capabilities for rotating pump components. Our experienced technical staff and full array of equipment results in re-installations with tolerances greater than factory specifications.

Most repairs have tolerances greater than factory specification. If that is not enough, let us know what you require.

CALL OR EMAIL FOR A QUOTE TODAY

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services

Geotechnical Drilling

Brotcke Well & Pump, Inc., (BWP) is a full-service, geotechnical and environmental drilling contractor incorporated in 1983. Our employees are trained to advance bore holes through overburden using both hollow steam augers and mud rotary drilling techniques. Their extensive experience with rock coring and other sampling methods (such as split spoons, shelby tubes, continuous samplers and piston samplers) assures our clients results. We have a complete array of drilling equipment to best serve our clients. Our equipment includes auger drilling rigs complemented with various sizes of drilling tools, steam cleaners, support trailers, service trucks, mobile cranes, decontamination equipment, protective clothing and safety equipment.

Our core set of geotechnical and environmental drilling services include:

- Geotechnical exploration including soil drilling, rock coring, standard split spoon sampling, thin wall Shelby tube sampling and piezometer installation.

- Environmental exploration including drilling and installation of groundwater monitoring wells, monitoring well decommissioning, environmental drilling and sampling.

- Our in-house laboratory is capable of performing a limited range of testing, such as visual soils and rock classification, gradation analysis and moisture contents.

- Full aquifer testing and groundwater quality testing.

- Borehole geophysical logging services

- In-situ testing services

- Installation of vibrating wire piezometers

CALL OR EMAIL FOR MORE INFORMATION

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services

Direct Push Drilling

BWP has a GEOPROBE 6610DTX. This versatile, track-mounted unit allows our crews access to almost any location. Speed and versatility is a key to quickly collect soil and gas samples allowing you to make better, well-informed decisions. BWP has tooling to extend sampling to any requested depth.

CALL OR EMAIL FOR MORE INFORMATION

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services

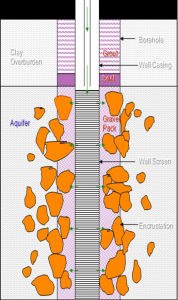

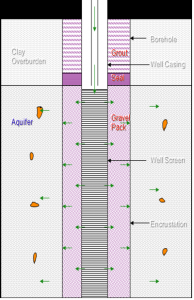

Water Well Design

Brotcke Well & Pump Company, Inc., (BWP) is a full service design-construct, municipal and industrial water well and pump service contractor. For over 30 years, BWP has been providing water-related engineering and construction services to clients throughout the Midwest.

BWP performs design-construct services ranging from complete hydrologic engineering investigations to locate new water supply aquifers to the selection of water well rehabilitation procedures. We have installed both alluvial and consolidated water wells from small capacity wells to installations over 3200 GPM. We specialize in alluvial gravel wall wells with outside diameters ranging from 20 to 60 inches. When required, double gravel wall wells have been recommended and installed to provide an effective filter for very fine sand formations. Dependent on the requirements, both direct rotary and reverse rotary drilling techniques are utilized.Well design is based on intended use, desired capacity and the aquifer’s hydrologic properties.

One or more test borings are required to define the aquifer at the desired well location. Gradation tests of representative samples allow selection of well screen slot size and gravel pack. The right well screen coupled with the proper gravel pack results in a highly efficient, sand free well – our project goal.

Well screens and casing ranging from 8″ to 36″ are commonly used with bore hole diameters ranging from 24″ to 60″.

BWP specializes in reverse circulation drilling – the preferred method in unconsolidated formations because it minimizes drilling fluid additives, assuring a high-efficiency well.

CALL OR EMAIL FOR AN ESTIMATE TODAY

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services

Water Supply Pumps

BWP is a full service sales and repair facility.

Our experienced technicians completely disassemble all units, inspecting and repairing parts on an as-needed basis to restore the unit to a like-new condition. Specialized components or standard pump parts can be fabricated in our custom machine shop to reduce downtime. Complete machine shop services are available to ensure timely and professional repair of both Vertical Turbine and Horizontal Pumps. Our re-installations have tolerances greater than factory requirements.

For new installations, our engineers work with your design team to select the pump that fits your specifications. Specialized components and standard pump parts can be fabricated in our custom machine shop. Most often, an existing pump can be rebuilt to a “like new” condition in our on-site machine shop.

We know pump maintenance and repair are critical to your operation. Downtime reduces productivity, quality of output and can create inconvenience with the general populace. We won’t let that happen to you. BWP services most makes and models, including:

- water pumps

- turbine pumps

- irrigation pumps

- blowers

- gear boxes

- compressors

- cooling tower pumps

All repaired pumps have tolerances greater than factory specification. If that is not enough, let us know what you require.

CALL OR EMAIL FOR A QUOTE TODAY

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services

Hydrological Investigation

Engineering water wells begins with a thorough understanding of the aquifer. Test holes are necessary to determine the aquifers integrity and locate an acceptable location for the new well. A location which has the following properties is highly desirable:

- Saturated Thickness – High

- Relative Density – Low

- Coarseness of the Sand – High

- Amount of Fines in the STRATUM – Low

From a single well to an entire field – BWP’s capabilities and track record speak for themselves. We provide our clients the data and analysis that allows them to make confident decisions.

A Hydrologic Engineering Study is approached as a multi-phase project at Brotcke Well & Pump, Inc. While there can be many variations from project to project, our approach is as follows:

- PHASE 1 Test Boring Program

- PHASE 2 Laboratory Sieve Analysis

- PHASE 3 Test Well Construction and Pump Testing

- PHASE 4 Engineering Analysis and Report

LOCATING NEW SOURCES OF GROUND WATER FOR OVER 35 YEARS

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services

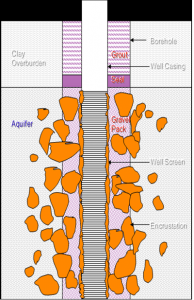

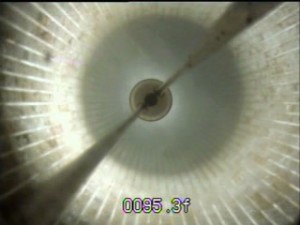

Reclaiming Efficiency

Over time, water wells become clogged and lose efficiency which directly relates to drinking water quality and quantity. Naturally occurring minerals precipitate out of solution as they enter the gravel pack and well screen of water wells. These minerals accumulate on the openings of the well screen and open spaces in the gravel pack, reducing the yield of the well. The precipitated minerals, along with oxygen introduced by the operation of the pump, cause an increase in biological activity, further reducing the yield of the well.

The environment in a water well is oxygen- and mineral-rich, ideal for bacteria to thrive and plugging to occur. If not cleaned, the gravel pack and well screens get clogged. The more clogged they get, the more costly it can be to rehabilitate a well. Left unattended, there is always the possibility of a system failure.

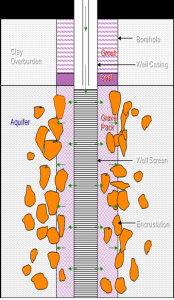

We won’t let that happen to you.

The Brotcke High Velocity Injection Process (U.S. Patent Number 5392814) is designed to clean this material mechanically by injecting a custom blend of chemicals at rates of up to 4,200 GPM with pressures of 60 PSI. By reversing the flow of fluid into the well at an extremely high rate, the loosened mineral and biological build up is removed from the well screen, gravel pack and native formation. Adding a custom blend of chemicals to the process achieves more effective cleaning by dissolving the mineral buildup and sequestering these materials so they can be removed from the well.

Our High Velocity Injection Technique has successfully rehabilitated hundreds of wells in the Midwest. Through this process, mineral deposits are removed from the formation as well as the well screen resulting in capacities much higher than those achieved by traditional methods of well cleaning.

Brotcke Well & Pump, Inc. (BWP) uses a patented High Velocity Injection Treatment process. It is a unique technique designed by BWP. A custom blend of chemicals engineered to meet each well’s specific requirements is injected and surged into the well and forced out into the formation.

All chemicals used by BWP are National Sanitary Foundation (NSF) approved.

Click the movie above to see the difference.

Our patented treatment system is designed to:

- clean the well screen with a combination of pressure and chemistry

- dissolve and remove build up

- sterilize the well environment

- improve flow capacity

CALL OR EMAIL FOR AN INSPECTION TODAY

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services

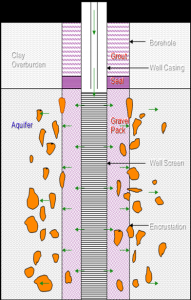

Airshock

The AirShock® Impulse Generator (AIG) is the latest, environmentally-safe water well rehabilitation process. It uses bursts of compressed gas to remove build-up from well screens, gravel packs and surrounding aquifers. It provides a “green” alternative to water well rehabilitation and development because it uses fewer (if any) chemical additives.

GREEN TECHNOLOGY

AIG fires automatically once every 2-3 seconds and each burst lasts just several dozens of milliseconds. Resulting shock waves and powerful water surges, produced by this process, successfully remove incrustation in the well screen, gravel pack and surrounding aquifer. In a very short time, a well is completely restored to the highest level of efficiency. The method is unique both in success and ease of setup and operation.

80 – 120% WATER WELL RESTORATION

AIRSHOCK® Impulse Generator is:

- Safe, environmentally friendly

- Highly effective for both screened and open wells

- Relatively short procedure of a few hours

- Well downtime 1-2 days only

- Used independently or in combination with chemicals

- Reliable equipment with negligible maintenance through years

- Contractor-owned

BWP, INC. | EXPERT WATER WELL & PUMP SERVICES

- Hydro-geologic Design Services

- Water Well Installation

- Water Well Rehab

- Pump Sales & Installation

- Complete Pump Service and Repair

- In-house Machine Shop Services

- Geotechnical & Environmental Drilling

- Direct Push Services